125 HP Electric Motors (125 Horsepower Industrial Motors)

125 HP electric motors deliver exceptional power and efficiency for heavy-duty industrial equipment operating under continuous load.

Built to perform in demanding environments such as aggregate plants, manufacturing lines, refineries, and large pumping systems, these motors provide reliable torque and long service life.

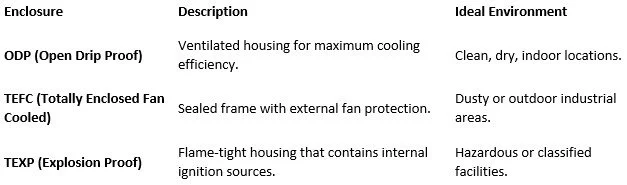

Available in ODP, TEFC, and Explosion-Proof (TEXP) enclosures, each 125-horsepower motor meets NEMA and CSA/UL standards for efficiency, safety, and durability.

What Does a 125 HP Motor Offer?

A 125 horsepower motor produces approximately 93.2 kilowatts of mechanical power, making it a top-tier choice for large-scale industrial machinery and high-load systems.

Typical NEMA frame sizes 444T – 445T incorporate reinforced bearings and ventilation channels for thermal stability and continuous operation.

✅ Key features:

Premium-efficiency design (NEMA Premium® compliant)

1800 or 3600 RPM speeds

230/460 V or 575 V 3-phase configurations

ODP, TEFC, and TEXP enclosure options

Low-vibration, high-torque operation for demanding processes

Enclosure Options — ODP, TEFC & TEXP

Each 125 HP motor is built to maintain peak performance and safety under varied environmental conditions.

125 HP Motor Specifications

Specification Typical Range / Option

Horsepower 125 HP

Frame Size 444T – 445T

Speed (RPM) 1800 / 3600

Voltage Options 230/460 V or 575 V (3-Phase)

Frequency 60 Hz

Service Factor 1.15 (Standard)

Efficiency Premium Efficiency

Enclosure Types ODP, TEFC, TEXP

Mounting Foot, C-Face, D-Flange, Vertical

Frame Material Cast Iron, Stainless Steel, Fabricated Steel

Every motor undergoes dynamic balance, temperature-rise, and insulation testing to ensure long-term operation under full load.

Common Applications for 125 HP Motors

The 125 HP category is trusted for high-power equipment and continuous-process installations such as:

Industrial pumps and compressors

Conveyors and crushers

Fans, blowers and ventilation systems

Mixers and agitators

Material handling equipment

Processing and production lines

Municipal and utility infrastructure

These motors deliver stable torque, high efficiency, and rugged longevity in round-the-clock operations.

Frame Materials and Construction

Cast Iron – Heavy-duty rigidity and vibration absorption for industrial environments.

Stainless Steel – Corrosion resistance for washdown and chemical applications.

Fabricated Steel – Customizable, lightweight frames for OEM systems.

Each unit is precision-machined to NEMA MG 1 standards and optimized for alignment and heat management.

Mounting and Voltage Options

Mounting Styles:

Foot Mount (Base Mount)

C-Face Mount

D-Flange Mount

Vertical Mount

Footless / Rigid Base

Voltage Options:

208 V, 230 V, 460 V, 575 V (3-Phase)

Dual-rated 230/460 V models

Fully VFD and soft-starter compatible

This flexibility simplifies integration into existing industrial systems and power infrastructure

Request a Quote or Spec Sheet

Looking for a 125 HP motor that matches your enclosure and performance requirements?

Our team can help specify the ideal unit by voltage, frame size, mounting, and brand to fit your operation.

Request a Quote or Request Spec Sheet for availability, pricing, and lead times on 125 HP electric motors from Brook Crompton, US Electric, and Worldwide Electric.

Related Products

Explore more horsepower and enclosure options: