ODP Electric Motors (Open Drip Proof Enclosures)

Open Drip Proof (ODP) electric motors are built for indoor environments where clean air circulation and cost-efficient cooling matter most. By allowing free airflow through the motor housing, an ODP design keeps windings cool without requiring sealed or fan-cooled enclosures. These motors are ideal for general industrial use in HVAC systems, pumps, compressors, and conveyors, where conditions are dry and well-ventilated.

What Is an Open Drip Proof Motor?

An Open Drip Proof motor — often shortened to ODP motor — features ventilation openings in the frame that allow outside air to flow directly over the internal windings.

This airflow keeps the motor cool during operation, improving energy efficiency and reducing material costs compared to enclosed designs.

The “drip proof” designation means the enclosure prevents liquid droplets falling up to 15° from vertical from entering, ensuring basic protection against minor condensation or spills. However, these motors are not sealed against dust or weather and are intended strictly for indoor or sheltered environments.

✅ In short:

Air-cooled through open ventilation

Protected against vertical drips

Lower cost than TEFC or TEXP enclosures

Ideal for clean, dry, indoor use

Benefits of ODP Motor Enclosures

ODP motors balance simplicity and performance. Their open design provides efficient cooling with minimal maintenance.

Key advantages include:

High Cooling Efficiency – Continuous airflow keeps internal temperatures low, extending motor life.

Lightweight Construction – Less housing material reduces weight, easing installation and handling.

Lower Cost – Simpler frame design and reduced material requirements make ODP motors cost-effective.

Easy Maintenance – Open access allows quick inspection and cleaning.

Energy Efficiency – Cooler operation translates into reduced losses under load.

These benefits make ODP electric motors a smart choice for facilities that maintain clean, dry air conditions.

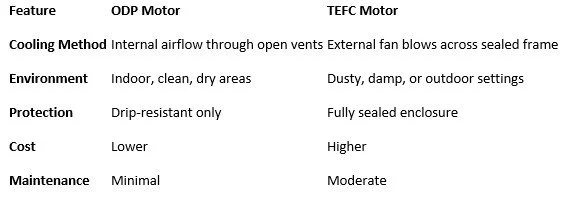

ODP vs TEFC — Choosing the Right Motor Enclosure

When selecting a motor, understanding enclosure type ensures proper protection and longevity.

Both ODP (Open Drip Proof) and TEFC (Totally Enclosed Fan Cooled) motors serve different environments:

✅ Rule of thumb:

If your environment is controlled and dry, ODP offers excellent value.

If dust, oil mist, or moisture are factors — upgrade to a TEFC electric motor for better protection.

Common Applications for ODP Motors

Open Drip Proof motors are widely used across light to medium industrial sectors. Their efficient cooling and cost savings make them suitable for:

HVAC air handling systems

Air compressors and blowers

Indoor pumps and conveyors

Machine tools and fans

Agricultural processing (in clean barns or grain elevators)

Each application benefits from the ODP motor’s direct-air cooling efficiency and simplicity.

Frame Sizes and Technical Specifications

Available in NEMA standard frames

Compatible with foot mount, C-face, or D-flange designs

Stock and custom configurations available from major brands including Brook Crompton, US Electric, and Worldwide Electric

Construction Options

Frame Material: Cast Iron, Stainless Steel, or Fabricated Steel

Mounting Styles: Foot, C-Face, D-Flange, or Vertical Mount

Voltage Options: 208, 230, 460, 575V 3-Phase; 120/240V Single Phase

Available Brands: Brook Crompton, US Electric, Worldwide Electric

These options allow exact matching to your process requirements.

Request a Quote or Specification Sheet

Looking for a specific ODP electric motor or open drip proof frame design?

Our experts can help you source the right model by horsepower, frame size, and brand.

Request a Quote or Request Spec Sheet to see available stock, pricing, and lead times.

Related Products

Explore other enclosure types: