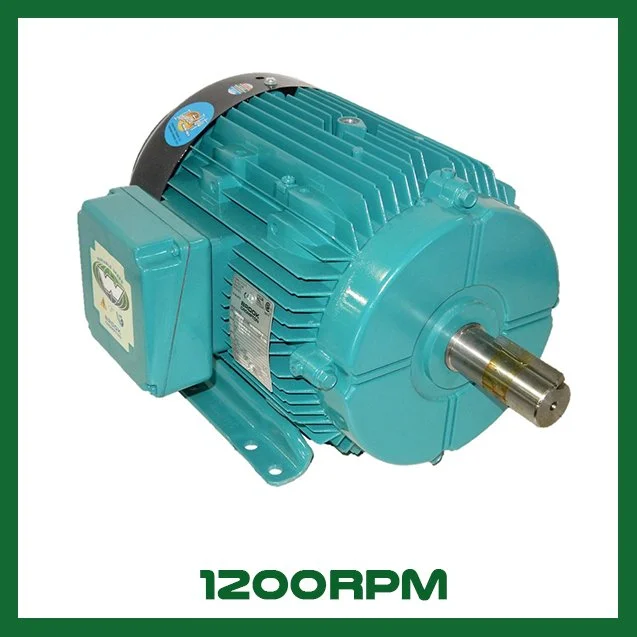

Electric Motors by RPM

Motor speed (RPM) directly affects torque output, system load, pump and fan performance, and mechanical integration.

Choosing the correct RPM ensures proper startup torque, flow and pressure control (for pumps & blowers), conveyor stability, and long-term reliability.

Crossman supplies 900, 1200, 1800, and 3600 RPM motors in ODP, TEFC, Explosion-Proof, and Washdown-Duty designs — all available in NEMA Premium efficiency and VFD-ready configurations.

Whether you're powering centrifugal pumps, positive displacement systems, conveyors, compressors, or industrial fans, proper RPM selection protects equipment and optimizes performance.

Browse Motors by RPM

Select the operational speed that matches your system requirements.

How Motor Speed Affects Performance

Torque Output Lower RPM = higher torque

Load Type Compatibility Pumps, conveyors, blowers all scale differently

Noise & Vibration Higher RPM → more vibration and noise

Bearings & Life Speed impacts mechanical stress & heat

VFD Control Variable speed = improved efficiency & flexibility

System Efficiency Proper RPM prevents over-sizing & wasted energy

Torque and speed are opposites — RPM selection protects equipment.

Where Each RPM Range is Used

900 / 1200 RPM Heavy conveyors, agitators, mixers, crushers

1800 RPM Pumps, conveyors, compressors, industrial fans

3600 RPM Centrifugal pumps, blowers, grinders, high-speed equipment

VFD & RPM Integration

All RPM ranges available as inverter-duty motors with:

Class F/H insulation

Shaft grounding options

Roller or sealed bearings

Precision balancing

Thermal protection options

VFDs enable precise RPM control for pumps, fans, conveying, batching & blending.

Request RPM-Based Motor Sizing

Not sure which RPM fits your load profile?

We assist with:

Pump & fan affinity law calculations

Conveyor torque requirements

Acceleration & start-profile analysis

Noise & vibration considerations

VFD settings & cable length evaluation

Request a Quote | Request Spec Sheet