Sensorless Artificial Lift Technology S.A.L.T.)

S.A.L.T. — Sensorless Artificial Lift Technology — is Crossman Automation’s advanced Variable Frequency Drive (VFD) solution designed specifically for oilfield pump control. Built on decades of field experience, S.A.L.T. provides precise pump-off detection, load balancing, and data visibility — all without downhole sensors.

The result: reduced failure rates, lower maintenance costs, and optimized production across ESP, PCP, Beam, and Rotoflex lift systems.

What Is Sensorless Artificial Lift?

Traditional artificial lift systems depend on downhole sensors that are expensive, prone to failure, and difficult to service.

S.A.L.T. eliminates that complexity by using advanced surface data algorithms to monitor motor torque, current, and speed — determining pump-off conditions and fluid load in real time.

By removing the need for physical sensors, operators gain:

Higher system reliability

Lower installation and maintenance costs

Improved production control across multiple wells

– How S.A.L.T. Works

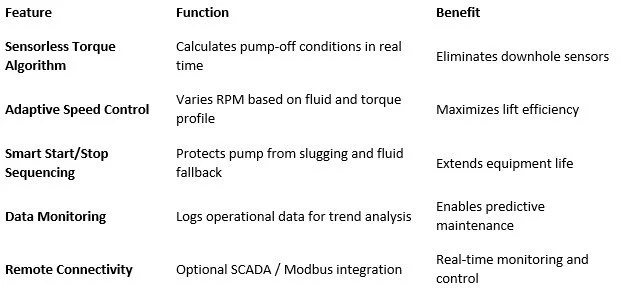

The S.A.L.T. controller continuously measures surface-level feedback from the motor and drive system to model downhole dynamics.

Using this data, it automatically adjusts speed and torque to maintain optimal pump fill, prevent gas lock, and reduce mechanical wear.

Compatible Pump Types

S.A.L.T. integrates seamlessly with all major artificial lift systems:

ESP (Electrical Submersible Pump) High-volume lift systems with torque-sensitive control.

PCP (Progressive Cavity Pump) Constant torque applications requiring gentle speed regulation.

Beam Pump Traditional rod-driven lifts with cyclical torque patterns.

Rotoflex / Hydraulic Pump Reciprocating systems with dynamic torque requirements.

Each system is optimized through customized torque maps and surface parameter tuning.

Key Benefits of S.A.L.T.

Operational Efficiency Real-time pump-off detection reduces wasted energy.

Equipment Longevity Smart torque control minimizes rod string and gearbox wear.

Production Optimization Maintains consistent drawdown and fluid level.

Lower Cost of Ownership No downhole sensor maintenance or replacements.

Fast Commissioning Plug-and-play configuration with pre-set lift profiles.

Scalable Integration Works with any standard 3-phase power system or VFD panel.

Why Sensorless Control Is the Future

Downhole sensors have always been the weakest point in artificial lift systems — prone to temperature failure, signal drift, and wire damage.

By using torque-based modeling and surface analytics, S.A.L.T. removes that dependency and gives operators the same insight — without the cost and downtime.

“S.A.L.T. allows us to see what’s happening downhole — without ever going downhole.”

— Crossman Automation Engineering Team

Integration and Compatibility

Compatible with Danfoss Drives and other industrial VFD platforms

Available in standalone panels or integrated skid systems

Supports Modbus, Ethernet/IP, and SCADA protocols

Designed for CSA / IEEE / NEMA compliance

Operates in -40°C to +60°C environments

S.A.L.T. can be retrofitted to existing drive systems or deployed in new field installations.

Typical Applications

Oilfield Artificial Lift Optimization

Field Retrofits & VFD Upgrades

Energy-Efficient Production Facilities

Multi-Well Lift Control Systems

Remote Pump Stations

Request a System Consultation

Ready to modernize your lift system?

Our engineers can evaluate your current setup and design a sensorless artificial lift control solution that improves uptime, efficiency, and production control.

Request a Quote or Request Engineering Consultation

Include: pump type, motor HP, voltage, and current lift system.

Related Categories

Low Harmonic VFD Systems →

Variable Frequency Drive Solutions →

Danfoss Drive Integration →