Stainless Steel Frame Electric Motors

Stainless-steel frame electric motors are engineered for the most demanding environments — from food and beverage plants to chemical, wastewater, and marine facilities where corrosion resistance and hygiene are mission-critical.

Constructed entirely from 304 or 316 stainless steel, these motors deliver superior protection against moisture, cleaning chemicals, and contamination, while maintaining NEMA-Premium efficiency and smooth, sanitary design for easy cleaning.

Crossman supplies washdown-duty and corrosion-resistant stainless motors across a full horsepower range, all meeting NEMA, CSA, and IP66/IP69K standards for durability and hygiene.

Typical Specifications

Specification Range / Detail

Frame Material 304 / 316 Stainless Steel

Horsepower Range 0.5 – 50 HP

Speed (RPM) 900 / 1200 / 1800 / 3600

Enclosures TEFC / TENV / Washdown Duty

Mounting Options Foot / C-Face / D-Flange / Vertical

Sealing Ratings IP66 / IP69K (available)

Surface Finish Smooth, polished exterior — no paint

Certifications NEMA / CSA / UL / IEC

Duty Rating Continuous duty (S1)

Key Advantages of Stainless Steel Motors

Full Corrosion Resistance Non-porous 304/316 stainless construction resists moisture, salt, and chemical attack.

Sanitary Design Smooth, crevice-free housing prevents bacterial buildup.

Washdown-Rated Protection IP69K sealing handles high-pressure cleaning and sanitization.

Long Service Life Sealed bearings and double-lip shaft seals protect internal components.

Maintenance Reduction No paint or coatings to chip or flake.

VFD Compatibility Inverter-duty windings for variable-speed washdown control.

Ideal Applications

Food & Beverage / Pharmaceutical

Meat & dairy processing plants

Bottling & packaging systems

Sanitary conveyors & mixers

Pharmaceutical blending & filling lines

Industrial / Corrosive Duty

Wastewater & desalination facilities

Marine & offshore environments

Chemical processing & plating systems

Pulp & paper washdown zones

Each stainless motor is designed to withstand frequent cleaning, humidity, and corrosive exposure without degradation or performance loss.

Enclosure & Sealing Options

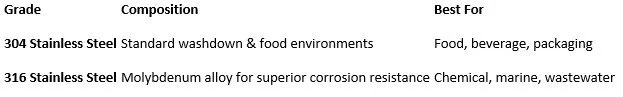

Stainless Steel Grades

Performance & Construction Highlights

Precision-machined stainless-steel end bells, rotor shaft, and hardware

Encapsulated windings for moisture isolation

O-ring sealed conduit box with stainless fittings

FDA-approved shaft seals and gaskets

Laser-etched nameplates (no adhesive labels)

Balanced rotor assemblies for vibration-free operation

Stainless vs Aluminum / Cast Iron Frames

Request a Quote or Spec Sheet

Looking for a stainless-steel electric motor for washdown, marine, or corrosive-duty environments?

Our team can specify the correct enclosure rating, frame size, and stainless grade for your operation.

Request a Quote or Request Spec Sheet