6600 Volt Medium-Voltage Electric Motors

6600-volt electric motors (6.6 kV) deliver the highest levels of power and reliability in the medium-voltage class — built for large-scale industrial plants, utilities, and infrastructure systems that demand continuous, efficient performance at thousands of horsepower.

These motors are designed for heavy process loads, long duty cycles, and harsh environmental conditions.

Available in TEWAC (Totally Enclosed Water-to-Air Cooled), TEAAC (Totally Enclosed Air-to-Air Cooled), and Weather-Protected (WPII) configurations, all models meet or exceed NEMA MG-1, IEEE 841, and API 541 standards.

Typical Specifications

Specification Range / Detail

Voltage 6600 V AC (6.6 kV)

Horsepower Range 500 – 5000 HP +

Speed (RPM) 900 / 1200 / 1800

Enclosures TEWAC / TEAAC / WPII / TEXP

Mounting Options Horizontal / Vertical P-Base

Frame Sizes 5000 Frame and larger

Cooling Systems IC81W (TEWAC) / IC611 (TEAAC) / IC01 (Open)

Frequency 60 Hz (Standard) / 50 Hz Optional

Standards NEMA MG-1 / CSA C390 / IEEE 841 / API 541 / IEC 60034

Advantages of 6600 V Motors

Massive Power Output Supports loads exceeding 5000 HP with exceptional torque stability.

Ultra-Low Current Draw High voltage minimizes conductor size and thermal loss.

Energy Efficiency Meets IE4+ equivalent efficiency levels in continuous duty.

VFD Integration Compatible with medium-voltage drives and soft starters.

Long-Range Reliability Built for uninterrupted 24/7 operation in remote installations.

These features make 6600 V motors indispensable for process-critical industrial systems where downtime is unacceptable.

Enclosure & Cooling Options

Typical Applications

Utility generation and distribution systems

High-pressure process and pipeline pumps

Industrial fans, compressors, and blowers

Mining and mineral processing drives

Steel mills and cement plants

Desalination and water-treatment facilities

6600 V motors provide stable, efficient operation under extreme load conditions, supporting multi-megawatt mechanical systems.

Performance and Design Features

Each 6.6 kV motor is engineered with:

Class H insulation systems with partial-discharge control

VPI (Vacuum Pressure Impregnated) windings for extended lifespan

RTD and thermistor monitoring for real-time protection

Insulated bearings and shaft grounding for VFD compatibility

Precision dynamic balancing to ISO 10816 vibration standards

API 541-compliant testing for critical process reliability

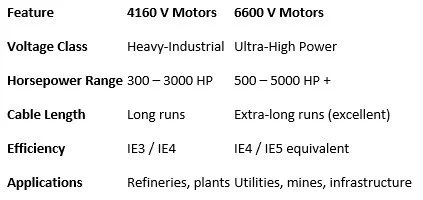

4160 V vs 6600 V Motors

Request a Quote or Spec Sheet

Looking for a 6600 V medium-voltage motor for your plant, mine, or power facility?

Our engineering team can assist with motor sizing, cooling system selection, and drive compatibility to ensure a seamless installation.

Request a Quote or Request Spec Sheet for detailed specifications and project pricing.